Infrared inspections can help you minimize damage to electrical systems in your Atlanta commercial buildings by rapidly identifying and correcting problems before they become more serious and more expensive to repair.

Building Diagnostics Group (BDG), headquartered in Atlanta, Georgia, is a multifaceted consulting firm with extensive expertise in infrared building science and water testing procedures that enable us to identify the cause and origin of most building failures.

Robert Scherer, President, is certified in Advanced Building Diagnostics and is an ITC Certified Level III Thermographer, Certified Indoor Environmentalist and Certified Mold Inspector with more than 15 years of thermography experience in a wide range of applications.

Our skilled team of professionals exclusively uses infrared camera equipment from FLIR, the world’s leader in infrared technology. This high-resolution specialty thermography equipment has made us one of the nation’s leaders in building science thermography.

What is Infrared Thermography?

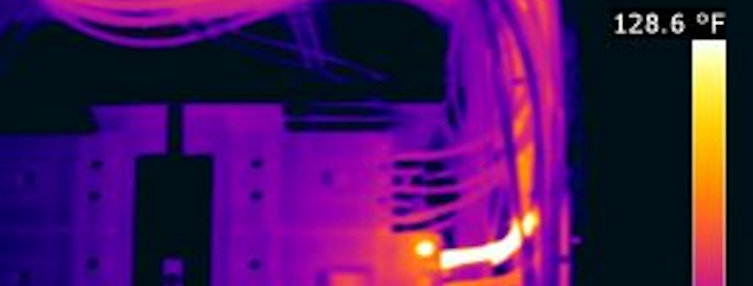

Infrared thermography (IR) uses specialized thermography cameras to measure the thermal energy emitted from an object. Thermal energy is light that is not visible because its wavelength is too long to be detected by the human eye. Unlike visible light, in the infrared world everything with a temperature above absolute zero emits heat.

IR thermography is the only diagnostic tool that lets you instantly visualize faults due to thermal patterns, enabling you to maintain the reliability of electrical and mechanical systems and resolve issues before it is too late.

About Infrared Electrical Surveys

As electrical faults develop, the electrical resistance of the offending item (switch, fuse, connections, breaker, etc.) will increase, leading to a corresponding increase in temperature until the item finally fails.

Heat is often an early symptom of equipment damage or malfunction, making it a key performance parameter to monitor in predictive maintenance programs.

Infrared thermography cameras are the first line of defense in a predictive maintenance program. Our technicians can quickly measure and compare heat signatures for each piece of equipment on the inspection route without disrupting operations.

Infrared predictive maintenance regularly checks the temperature of critical equipment, enabling us to track operating conditions over time and quickly identify unusual readings for further inspection.

By monitoring equipment performance and scheduling maintenance when needed, the experts at BDG can help you eliminate the likelihood of unplanned downtime due to equipment failure, spend less on “reactive” maintenance fees and equipment repair costs, extend the lifespan of machine assets, and further maximize maintenance and production. We can detect, document, and provide written reports of electrical components long before they fail.

An annual electrical/mechanical survey will:

- Accurately pinpoint problems

- Prevent expensive catastrophic failures

- Improve efficiency

- Reduce non-productive downtime

- Avoid shutdowns and lost revenue

Building Diagnostics Group will help you protect your investment by providing high-quality commercial electrical infrared inspections in Atlanta or elsewhere in the nation. For more information, call us at (404) 946-9939 or contact us online to talk about your project.