It is estimated that up to 40 percent of all commercial roofs will develop leaks within the first year of service. The average life span of these roofs is seven to ten years, but they can last as long as twenty years if they are correctly installed and property maintained. Commercial roof maintenance is a vital part of keeping your property investment performing for you.

Far too often, the cause of a roof failure is the absence of proper maintenance and inspection. Periodic inspections and routine maintenance to correct deficient conditions can significantly increase the long-term service life of any roof system. A regularly scheduled maintenance program will avoid expensive emergency costs that can arise without routine maintenance.

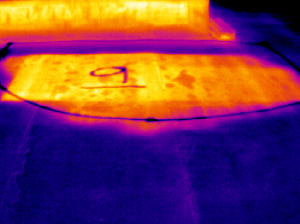

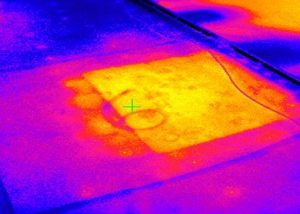

Infrared roof inspections work on the principle that different materials in the roof have different thermal masses. In the daytime, the sun heats the roof structure. After the sun sets, the roof begins to cool. If there is a leak in the roofing membrane, the insulation inside the roof will become wet. The wet insulation has a higher thermal mass than the rest of the dry roof structure. Because of the difference, the “wet” areas will maintain heat energy longer than other areas, providing the infrared thermographer with a clear picture of the damaged areas.

We can easily detect failures in low slope commercial roof systems. Infrared roof inspections are fast and affordable, and they provide accurate observations of the condition of an existing roofing system. Our team can evaluate up to 300,000 SF of roof area in a single visit via our walk-over method, or we can evaluate millions of square feet by utilizing our aerial sUAS service. Infrared imaging stands above all other methods in prolonging the life of a commercial roof system. Infrared roof inspections are a non-contact and non-destructive testing method to determine active roof leaks, and the infrared camera allows a professional thermographer to scan large areas of the roof from a distance. Traditional roof inspection methods require a time-consuming grid-type contact search (capacitance testing) that involves drilling holes (core sampling) in the roof membrane. This inspection method is definitely not recommended!

We also utilize the Tramex Dec Scanner™ that can detect as little as 3% moisture content in most roof systems and detects moisture up to 3 inches below the roof surface. The combination of these two technologies provides accurate non-destructive results. All BDG infrared roof inspections are conducted according to the ASTM C 1153 “Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging.”

We provide a written report that includes IR images and digital photos of each “anomaly” or fault found during our visit. By request, we can mark each suspect anomaly on the roof so it can easily be assessed and/or repaired by a licensed roofing company.

Give us a call to discuss your next project.